Project Description

Location: Biloela, Queensland

Year Completed: 2019

Job Type: Industrial Cooling Tower Repair

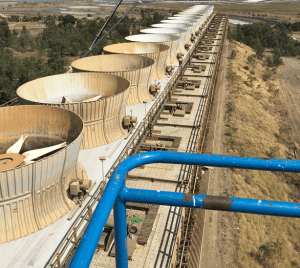

For the 2019 maintenance shutdown of Callide power station unit C, Marley Flow control was engaged by CS Energy to complete replacement of the unit C cooling tower fan deck. Due to the time frame of the shutdown, it was imperative that the fan deck replacement was completed in the most time efficient manner. As the largest cooling towers in the southern hemisphere, the experience of the Marley flow crew ensured that that fan deck was completed on time and to the satisfaction of the client.

During mobilisation of this job, Marley Flow created a detailed methodology that involved prefabricating the fan deck components and packed them in the specific laying order. This eliminated the high risk of cutting the fan deck in the plenum, and leads to greater quality control of the deck boards. Additionally, Marley developed bespoke tools that allowed simple and effective lifting of the fan cowling, preventing the need for a 120T crane throughout the duration of the job, and simplifying the onsite tasks. This pre-project organisation allowed Marley Flow to complete the job within the 3-week time frame, and without any injuries.

To complete the job the Marley Flow crew split into 3 teams, the first team went ahead and removed all the bolts from the fan cowling and lifted it up off the fan deck using in-house designed tools. This team was followed by the deck removal team who removed all the deteriorated plywood decking. Finally, the deck replacement team came through and installed the new fiberglass fan deck, and replaced any broken or damaged timber as required. Once installed the cowling team came back and reinstalled the cowling back onto the fan deck. This process allowed the works to progress repeatedly from cell number 1 through to cell number 18 quickly and efficiently.

Further to the work methodology, Marley Flow was able to coordinate its works in such a way to not disrupt the other works being completed during the shutdown, specifically the Programmed Maintenance cleaners who were working in the cold-water basin, and the MHPS fitters replacing the fire system.

Marley recognised the importance of thorough pre job organisation, skilled trades and project management to successfully complete the project safely and within the given time frame. This project demonstrated that Marley Flow are capable of delivering successful shutdown projects, for both ourselves and the client.