Details

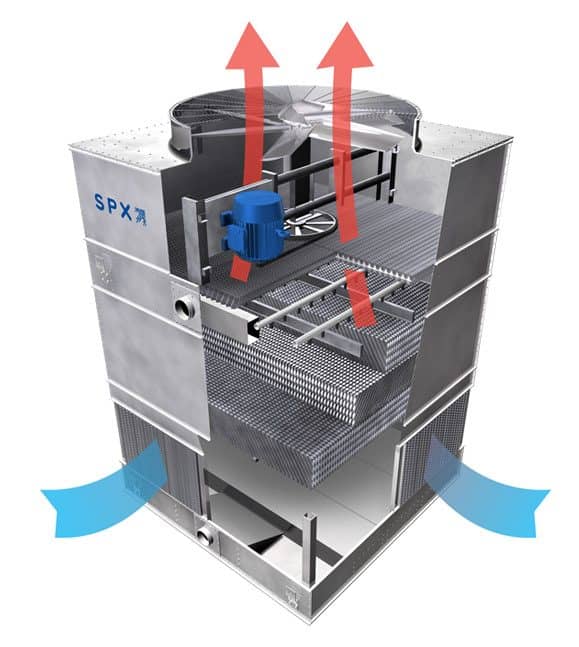

“Where space is limited or otherwise restricted, a counterflow cooling tower may be a perfect fit. In addition to taking up less site space, counterflow cooling towers may have a lower installed weight. Plus, piping costs can be reduced because a single inlet is usually standard. Triple-pass inlet louvers limit the sunlight entering the collection basin to reduce the potential for algae growth. Counterflow cooling towers offer easy access to the collection basin from all sides. The wet surface is totally enclosed for protection from environmental elements, and the MD cooling tower utilizes a corrosion-resistant spray system.

Unmatched Reliability

Heavy-duty construction, high-performance design, and our five-year mechanical warranty ensure consistent, fully rated cooling over a wide range of flow and temperature requirements.

Smaller Footprint

Induced-draft counterflow cooling tower design requires less plan area than crossflow cooling towers for many HVAC and light industrial duties. And because the cooling tower’s size typically results in less steel used, its reduced weight requires less support structure.

Low Energy Consumption

Induced-draft counterflow mechanical equipment minimizes the energy consumption by providing a lower fan energy requirement than centrifugal fan counterflow cooling towers.

Ease of Maintenance

SPX Cooling Technologies has worked hard to address the maintenance difficulties long associated with counterflow cooling towers. Our MD cooling tower provides larger access doors, easily removable block fill and other features that simplify maintenance.

Low Sound

The CTI-certified Marley MD cooling tower comes standard with our low-sound fan, suitable for most noise-sensitive situations. Multiple fan and attenuation options are available to meet more stringent sound requirements.

Independently Validated Sound Data

Marley towers are the only package cooling towers tested per CTI ATC-128 test code by third-party CTI-licensed test agents and certified acoustical engineers. MD sound levels are independently verified to meet published sound levels.

Superior Water Management

To address the “splash-out” problem typically found in other manufacturers’ counterflow cooling tower designs, SPX introduces an industry first: a triple-pass inlet louver that conserves water and improves winter operation.

FM Approval

For applications of two or more cells, the MD tower conforms to the FM Approval Standard for cooling towers, Class Number 4930.”