Cooling towers may be the most efficient way of removing heat from a facility but like all mechanical equipment, they create noise. This noise is often under strict limits within building codes or project requirements, so it’s essential to abide by these rules and ensure that the noise levels are in accordance.

Since 2002, Marley Flow Control has been the industry leader in the manufacturing of cooling towers. We are an Australian-owned and operated brand that offers a high level of expertise and an extensive range of products that are ready to order. Our wealth of knowledge has allowed us to work with some of the country’s largest businesses and corporations we are pleased to call our clients.

As industry leaders, we have a high level of expertise and can provide a wide range of cooling tower services. If you need help with cooling tower noise control, contact our highly experienced team to discuss your options today.

How can you reduce cooling tower noise? Read on to learn all you need to know about cooling tower noise control.

What causes cooling tower noise?

There are two main factors that cause cooling tower noise.

- Mechanical noise – the sound of any mechanical components such as fans, motors, gearboxes or belt drives operating.

- Water noise – the sound of the water spraying and falling within the tower.

What you need to know before you address the noise

The location of the receiver

Identify the location of the noise-sensitive receiver. Identify the distance between the receiver and the tower and the direction of the receiver from the tower.

The receiver is an observer at the location of interest where the noise is to be measured or observed. For example, you may be planning to install your tower next to a residential building. In this case, the receiver is the building, as any noise your tower produces will negatively affect the people who live there.

Noise targets

Not every location has noise restrictions – or a ‘noise target’. But if your facility does, it’s important to understand what that noise target is and if it differs from day to night. Night noise typically has a lower, stricter limit as to not disturb people during the evening, or while they sleep.

Noise targets are normally given in decibels A-weighted (dBA). The dBA value may be a pressure level or a power level and it’s imperative to know which is being specified.

How to reduce cooling tower noise

The best way to reduce cooling tower noise is to plan before installing your tower. With a little forethought and expert design, you can save yourself a lot of time, money and stress.

There are many other ways to reduce cooling tower noise. Not all options will be suitable due to space, location or resources. These principles also apply to large, field-erected towers.

We have listed nine options from most cost-effective to most expensive.

Turn the tower

If you have a crossflow tower, reducing noise could be as simple as turning the cased-face towards the receiver. This could cut down noise as much as 12dBA.

Move the tower

Move your tower away from the receiver. Doubling the distance between the tower and receiver can reduce noise approximately by 6dBA.

VFD

Fit a cooling tower with a VFD – variable frequency drive. This allows you to control fan speed and airflow while still maintaining efficient operation.

If your noise target differs during the evening, you can lower the fan speed to abide by those targets.

Quiet fan

Opt for a ‘quiet’ or ‘ultra-quiet’ fan. While more expensive, these fans run more slowly without comprising the airflow.

Oversize the tower

By choosing a bigger tower than what you need, you are allowing the fan to run slower with less power. The slower a fan runs, the quieter it will be.

Choose the right tower

Choose the correct type of cooling tower. Packaged cooling towers come in four arrangements:

- Forced draft tower

- Induced draft tower

- Crossflow tower

- Counterflow tower.

Each type of cooling tower has different characteristics, including the noise they produce. For example, force draft towers are noisier due to their inefficient fans. So choose the best type of tower for your needs.

Read our blog here to learn more about the different types of cooling towers.

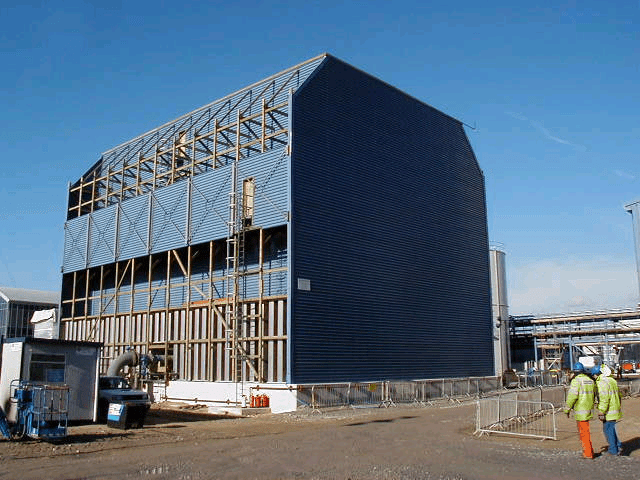

Install a wall

Install a solid or acoustic barrier wall between your cooling tower and receiver. The noise reduction will depend on the size and location of your wall, as well as how it’s constructed.

Splash attenuation

For counterflow cooling towers, consider installing a splash attenuation – a ‘matting’ in the water designed to absorb sounds. This can reduce air inlet levels up to 5dBA.

Crossflow towers do not need splash attenuation since they don’t have falling water or a ‘rain’ zone.

Discharge attenuation

Installing a discharge attenuation can reduce sound levels by 5dBA or more. In this case, the attenuation is a series of panels that air flows through, limiting noise. These can be installed on either the top or side of the cooling tower.

However, an attenuation can choke the airflow to the tower, causing a performance derate. This is when the cooling ability of the tower is negatively impacted. As a result, you may use more energy and resources to ensure that your tower runs efficiently.

We can repair and inspect your cooling tower

If your tower should exhibit an increase or change to the noise it usually produces, it may indicate a mechanical problem.

Marley Flow Control offers a comprehensive cooling tower inspection and repair service. We offer repair work on the fill and mechanical components and a full functional annual assessment. Afterwards, we provide a comparison between a comprehensive refurbishment or a new cooling tower.

We can perform repairs during industrial plant shutdowns and can tailor a programme to suit you. We can also repair your mechanical components, such as gearboxes and fans, as well as recondition your large diameter fans at our in-house facility in Western Sydney.

Our experienced team has the skills and equipment to fit new motors, driveshafts, gearboxes and fans in the field, including long laser alignments of up to four metres.

Find out how we can use our engineering experience to help find the right solution for your business needs. Contact us here for a free quote.